Today, we talk about the artificial intelligence changes logistics, how AI is changing the logistics industry?

How Ai is changing the logistics industry today?

Automation will continue to grow and expand logistics operations through the use of technologies such as artificial intelligence.

Automation uses technology to augment the workload of humans in a myriad of tasks. In logistics, the potential for automation is enormous and the benefits are significant, especially when operations experience dramatic changes or increased demand.

Scaling up operations often requires additional staff that is often not immediately available, especially when other industries are also in demand. Responding quickly to market fluctuations requires quick action and additional capacity throughout the operation.

As demand changes, logistics automation can enable rapid capacity growth. When used strategically, logistics automation can increase productivity, reduce human error, and improve efficiency.

With the proper logistics automation software, hardware, and platform resources in place, the impact on operating expenses during periods of low demand is minimal and far less than maintaining significant human resources. As demand increases, capacity is in place and ready to be activated. While this gives logistics companies the flexibility they need to respond quickly to changes in demand, there is also the opportunity to do more.

AI amplifies the impact of logistics automation, that was how AI is changing the logistics industry.

Introducing artificial intelligence (AI) into logistics automation amplifies the impact of AI. AI reduces errors in common semi-skilled tasks, such as sorting and classifying products.

For example, autonomous mobile robots (AMRs) can improve package delivery, including last-mile delivery, which is often the most expensive. AI helps AMRs with route planning and feature recognition, such as people, obstacles, delivery portals, and doorways.

Integrating logistics automation into any environment presents challenges. It can be as simple as replacing repetitive processes with powered conveyors, or as complex as introducing collaborative, autonomous robots into the workplace. When artificial intelligence is added to this automation and integration process, the challenges become more complex, but the benefits will be increased as well.

As the solution becomes more connected and more aware of all the other stages in the process, the efficiency of the individual automation elements increases. Moving AI closer to where data is generated and acted upon is called edge AI. The adoption of edge AI has redefined logistics automation.

Edge AI is growing rapidly and its use is not limited to logistics automation. The benefits of placing AI at the edge of the network must be balanced with the availability of resources, such as power, environmental operating conditions, physical location, and available space.

How AI is changing the logistics industry by edge inference

Edge computing brings computing and data closer together. In traditional IoT applications, most data is sent over the network to a (cloud) server where it is processed and the results are sent back to the edge of the network, such as a physical device.

Cloud-only computing introduces latency, which is unacceptable in time-critical systems.

An example of edge computing at work is capturing and processing image data from local packages during picking, allowing a logistics automation system to respond within 0.2 seconds.

Network latency in this part of the system slows down the sorting process, but edge computing is removing this potential bottleneck.

While edge computing brings computing closer to the data, adding artificial intelligence to the edge can make the process more flexible and even less error-prone. Similarly, last-mile logistics relies heavily on humans, but AMR using edge AI improves this as well.

Adding AI has a significant impact on the hardware and software used in logistics automation, and there are a growing number of potential solutions.

Often, the solutions used to train AI models are not suitable for deploying models at the edge of the network. The processing resources used for training are designed for servers, where resources such as power and memory are virtually unlimited. At the edge, both arithmetic power and storage are limited.

How AI is changing the logistics industry trends in heterogeneous architectures

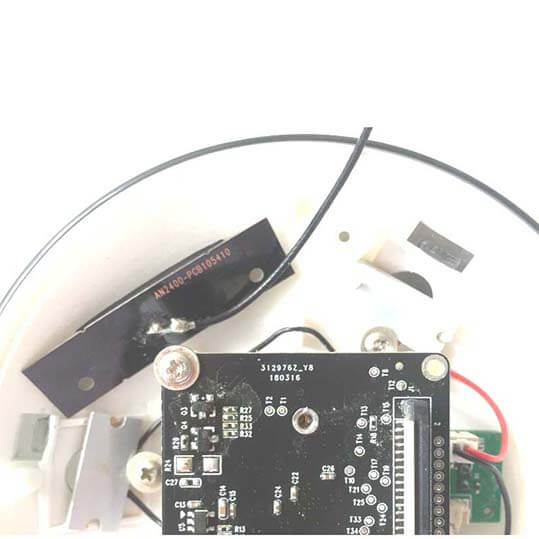

On the hardware side, large multicore processors are not well suited for edge AI applications. Instead, developers are turning to heterogeneous hardware solutions optimized for edge AI deployments.

This includes CPUs and GPUs, of course, but it extends to application-specific integrated circuits (ASICs), microcontrollers (MCUs), and FPGAs. Some architectures, such as GPUs, excel at parallel processing, while others, such as CPUs, are better at sequential processing.

Today, no architecture can truly claim to provide the best solution for AI applications. The overall trend is to configure systems using hardware that provides the best solution, rather than using multiple instances of the same architecture.

This trend points to heterogeneous architectures, where there are many different hardware processing solutions configured to work together, rather than homogeneous architectures that use multiple devices, all based on the same processor.

The ability to introduce the right solution for any given task, or to consolidate multiple tasks on a given device, provides greater scalability and the opportunity to optimize performance per watt and/or per dollar.

Moving from homogeneous system architectures to heterogeneous processing requires a large ecosystem of solutions and the proven ability to configure these solutions at the hardware and software levels.

That’s why it’s important to work with vendors that have significant Tier 1 relationships with all the major chip vendors that provide solutions for edge computing and work with them to develop scalable and flexible systems.

In addition, these solutions use common open-source technologies such as Linux, as well as specialized technologies such as the robotic operating system ROS 2. In fact, a growing number of open-source resources are being developed to support logistics and edge AI.

From this perspective, there is no single correct software solution, and the same is true for the hardware platforms running the software.

A Modular Approach to Automated Edge Computing of How AI is changing the logistics industry

To increase flexibility and reduce vendor lock-in, one approach is to use modularity at the hardware level, making the hardware configuration in any solution more flexible. In fact, hardware-level modularity allows engineers to change any part of the system hardware, such as the processor, without causing a system-wide disruption.

The ability to upgrade the underlying platform (whether it be software, processors, etc.) is especially important when deploying new technologies such as edge AI.

Each new generation of processor and module technology typically provides a better power/performance balance for inference engines running at the edge of the network, so these performance and power gains can be quickly leveraged.

Minimizing disruptions to the overall logistics automation system, and edge AI hardware system design is a clear advantage.

Modularity in hardware is extended to software through the use of microservice architectures such as Docker and container technologies.

If a more optimized processor solution is available, even if it comes from a different manufacturer, the software utilizing that processor is modular and can be used in place of the previous processor’s modules without changing the rest of the system.

Software containers also provide an easy and powerful way to add new functionality, for example, for running AI at the edge.

The software within the container can also be modularized.

The modular and container approach to hardware and software minimizes vendor lock-in, which means the solution is not dependent on any particular platform. It also increases the abstraction between platforms and applications, making it easier for end-users to develop their own platform-independent applications.

How AI is changing the logistics industry conclusion

Then, how AI is changing the logistics industry?

Deploying edge AI in logistics automation does not require replacing the entire system. Start by evaluating the workspace and identifying the phases that can truly benefit from AI-driven automation. The primary goal is to increase efficiency while reducing operational expenses, especially in times of labor shortage to cope with increased demand.

A growing number of technology companies are working on AI solutions, but these companies are typically targeting the cloud, not edge computing. At the edge, conditions are very different, resources may be limited, and dedicated private communications networks may even be required.

Automation will continue to grow and expand logistics operations through the use of technologies such as AI. These system solutions need to be designed for harsh environments, very different from the cloud or data center. We address this issue using a modular approach that offers highly competitive solutions, short development cycles, and flexible platforms.

After the whole reading, you may know how AI is changing the logistics industry.

Besides how AI is changing the logistics industry article, you may also be interested in the below articles.

PCB Antenna VS. External Antenna

Ceramic Antenna VS. PCB Antenna, A Comparison Guide

Wifi vs. 5G, is 5G better than Wifi?

Mobile Networks’ Evolution From 1G To 5G